LED Neon Flex Tube Silicone Gel Flexible LED Strip Silicone extrusion IP67 Waterproof for Decoration

We Newstar produce all kinds of neon flex led silicone extrusion, welcome enquiry.

- Description

- Inquiry

LED Neon Flex Tube Silicone Gel Flexible LED Strip Silicone extrusion IP67 Waterproof for Decoration

Silicone Neon LED Strip Tube, as a kind of protective material to led strip, fabricated by the integrated silicone extrusion molding technology with ingress protection up to IP67 and good performance of resistance to salt water, chemicals, UV radiation, and fire.

Which can be widely used for indoor & outdoor stylish design, like roof corners, corridors & edges, and other places for decorative lighting.

Product Features:

1. Wide applicability, easy to install and maintain;

2. Extremely luminous, with wide viewing angle;

3. Unique waterproof technique;

4. Environmental conservation, long lifespan;

5. 3 Years Warranty.

Product Description:

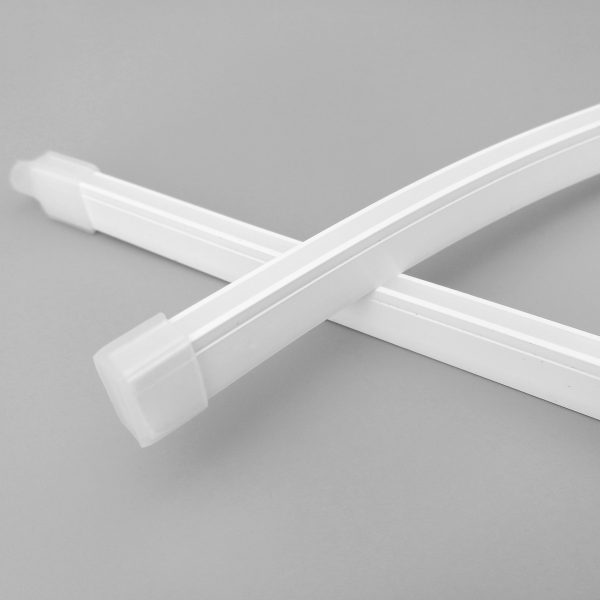

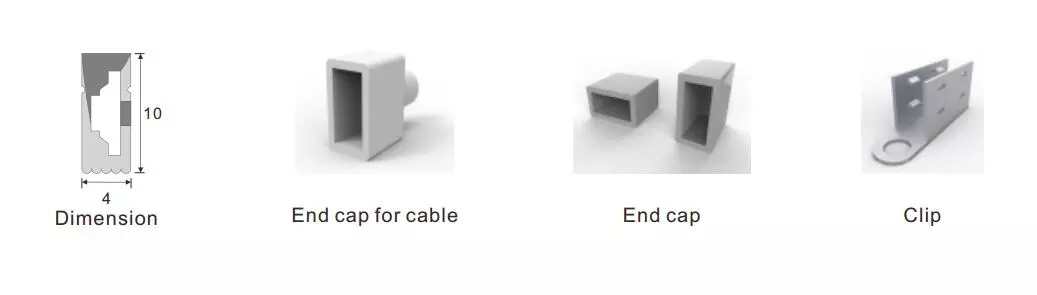

0410 Silicone LED Flex extrusion

Suitable PCB Width: 6mm

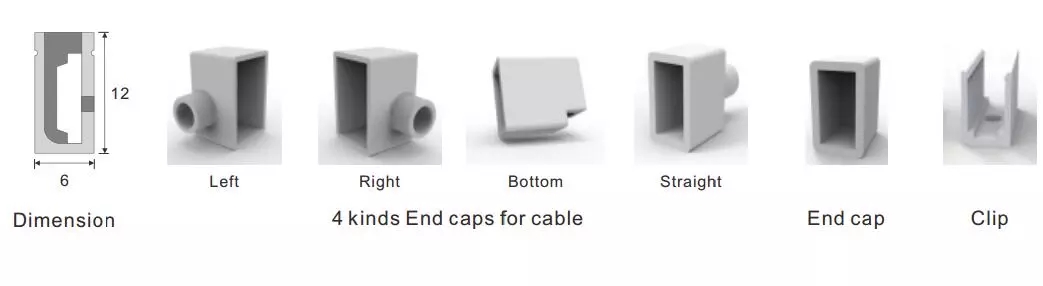

0612 Silicone Neon Flex extrusion

Suitable PCB Width: 8mm

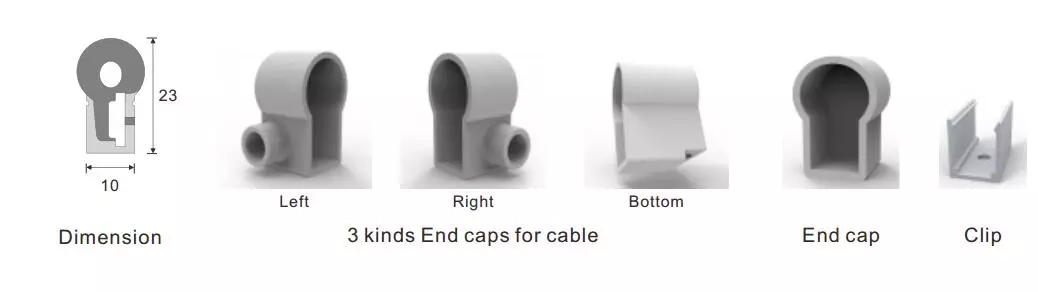

1023 Silicone LED Flex extrusion

Suitable PCB Width: 10mm

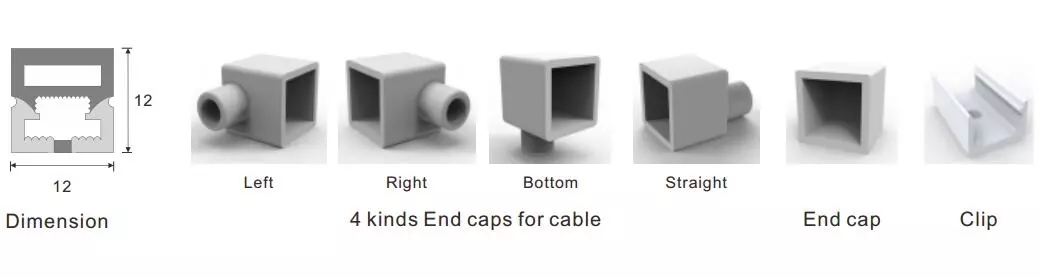

1212 Silicone Neon Flex extrusion

Suitable PCB Width: 8mm

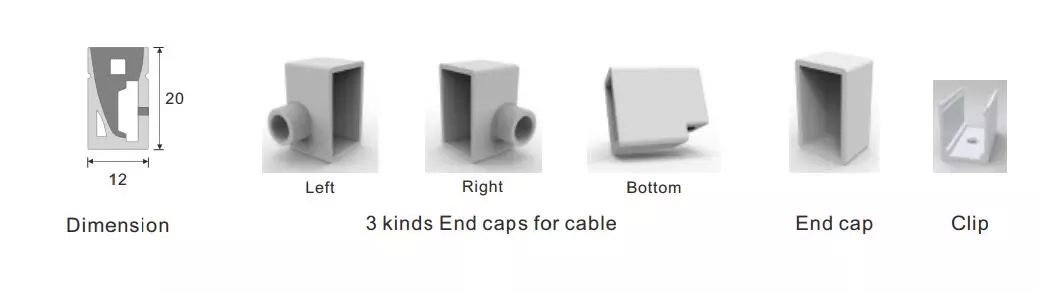

1220 Silicone LED Flex extrusion

Suitable PCB Width: 10mm

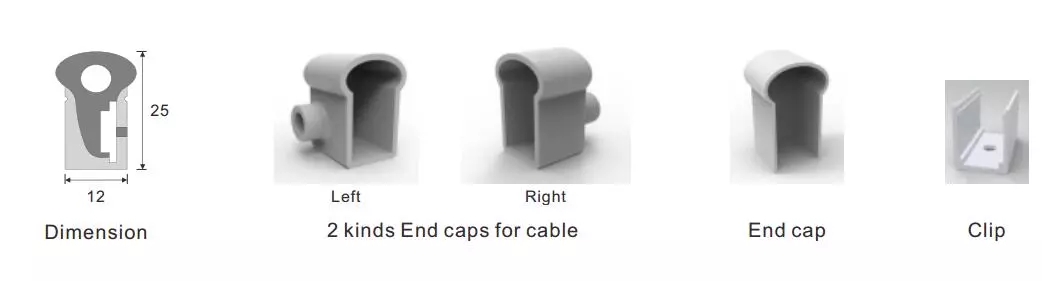

1225 Silicone Neon Flex extrusion

Suitable PCB Width: 10/12mm

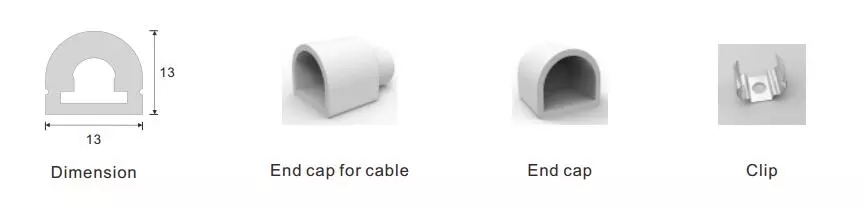

1313 Silicone LED Flex extrusion

Suitable PCB Width: 8mm

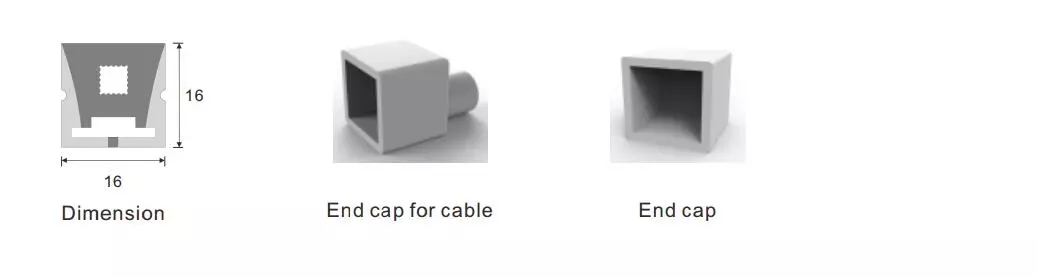

1616 Silicone Neon Flex extrusion

Suitable PCB Width: 10/12mm

HOW TO USE

Note: Each silicone sleeve has a white cotton thread inside it, which is used to pull the LED light strip into the sleeve. The line is the same length as the silicone casing!

How to insert LED strip Light to the flex tube? (wear the casing)?

Before wearing the casing, we need to confirm the length of the two belts, the length of the led strip we used, and the length of the neon flex tube casing. Since the length of the led strip is determined by the minimum length that can be cut by itself.

Before the light strip is cut, it is necessary to compare the strip with the light strip at the place where it needs to be installed, and then find the top of the strip according to the actual situation.

The scissors hole is cut off, this is the length of the light bar, and then the sleeve with the same length as the light strip can be cut.

Something you need to use during the operation is:

![]()

Step 1

Tie the traction line of the neon flex strip inside the flex tube to the line of the led strip light.

![]()

Note: the line must be tied firmly to avoid falling off.

Step 2

The beaded side of the led light strip corresponds to the side of the lamp bead inside the led flex tube bushing that is stuck in the slot.

![]()

Step 3

Then lay the strip and the neon flex tube bushing flat, and start to pull the strip slowly from the other side of the bushing until the led strip is pulled to the other side of the neon flex tube bushing.

![]()

Note: if the length of the casing used is less than or equal to one meter, the light strip can be passed directly without the need to tie the traction line.

Step 4

Light up a test to see if the led flex tube works properly. If there is any problem, you can directly pull out the light strip, repair or replace it, and re-put it in.

Step 5

Run the neon plug over the light line and then push the silicone into the plug slot.

![]()

Step 6

Insert the plug at the end of the neon flex tube into the silica gel and install it on the neon tube.

![]()

Note: if the outlet mode of the light strip is waterproof joint or head, in this case, the wire shall be first passed through the plughole of the neon tube sleeve, then the wire shall be welded to the DC surface of the light strip, and finally silica gel shall be used to install the plug.

![]()

Key points of casing wearing:

1. The length of the lamp strip must be measured carefully and the value must be accurate to ensure the best installation effect.

2. When pulling the light belt traction rope, be sure to put the light belt and the casing straight without bending to ensure smooth penetration

3. Be sure to turn on the power to check whether the light strip works normally after wearing the casing, so as to avoid unnecessary work.

4. Silica gel should be full, pay attention to the plug around the wall, and wire through the hole should be made of glue, so as to avoid a long time off the plug.

5. After the plug is installed, make sure that the silica gel is fully dried before using the neon light belt to ensure that the plug is stuck firmly.

Products List:

![]()